Design Guidelines contd 3. An informational resource for anyone looking to bond plastics this completely updated 96-page guide provides detailed technical information on the.

Structural Bonding Alternatives For Plastics Plastics Decorating

Adhesive permanently bonds difficult-to-bond plastics and rubbers together or in combination with metals andor composites.

. The Loctite Design Guide for Bonding Plastics Volume 62 Plastics have become an integral part of everyday life. In the beginning there were adhesives. The Loctite Design Guide for Bonding Plastics provides bond strength data for 30 substrates including ABS delrin nylon polycarbonate polypropylene polyethylene and PVC.

Courtney has worked on projects in which engineers. The most common procedure is a solvent wipe followed by. The data can be used to make correlations to products and understand how surface treatments will.

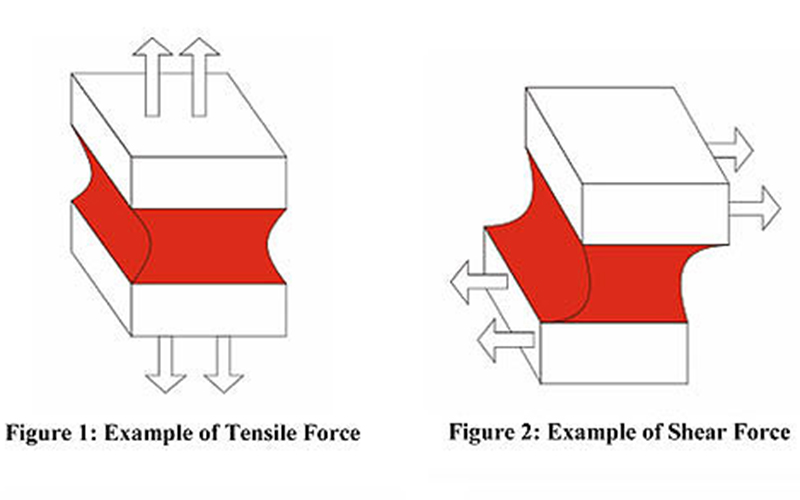

For 50 plus years Loctite has delivered customers with innovative sealing and adhesive solutions. Difficult-to-bond plastics include polyolefins such as polyethylene and polypropylene fluoropolymers such as Teflon acetal resins and thermoplastic vulcanizates such as Santoprene. The design of the bondline is mainly determined by BONDING GAP The size of the bonding gap determines whether it is a rigid or a flexible joint independent of the adhesive.

With 5000 plus patents Loctite leads the category and provides the widest line. Even products which appear to be composed exclusively of metals are usually coated sealed or adhesively joined. Loctite Design Guide for Bonding Plastics.

For the first two volumes of this guide this was accomplished using two basic approaches. The Solution Bond Strength Information This guide is designed to indicate the bondability of the 30 most commonly used plastic types without performing the impossible task of actually testing each individual grade. Henkel Corporation Rocky Hill CN has updated and reintroduced its Loctite Design Guide for bonding plastics to simplify the challenge of determining the most effective adhesiveplastic bonding combinations.

3M Scotch-Weld Epoxy Adhesive. For 50 plus years Loctite has delivered customers with innovative sealing and adhesive solutions. 2 The LOCTITE Design Guide for Bonding Metals Volume 6 The LOCTITE Design Guide for Bonding Metals Volume 6 3 LOCTITE Adhesive Overlap Weld 14 Nut Bolt Pop Rivets 0 Double-sided Tape 500 1000 1500 2000 2500 3500 4000 4500 Shear Stress lbf 3000 144 252 220 385 260 Advantages of LOCTITE Structural Adhesives vs.

It also details adhesive shear strengths with commonly used plastics paired with select Henkel adhesives. The Problem The LoctiteDesign Guide for Bonding Plastics Volume 62Plastics have become an integral part of everyday life. Design Guide for Bonding Plastics Volume 5 Cyanoacrylate Adhesives General Description Cyanoacrylates are one-part room-temperature-curing adhesives that are available in viscosities ranging from water-thin liquids to thixotropicgelsWhenpressedintoathinfilmbetweentwosurfaces.

In fact adhesives selection often takes place late or even last in the design process. Loctites continuous commitment to improvement insures constant progress of frustration-free dispensing systems and breakthrough formulations. The guide also presents shear strength data on 23 Loctite adhesives including cyanoacrylates epoxies hot melts light cure acrylics polyurethanes silicones and no.

It would be difficult to identify a manufacturing process which does not use plastics in one form or another. When pressed into a thin film between two surfaces cyanoacrylates cure rapidly to form rigid. It would be difficult to identify a manufacturing process which does not use plastics in one form or another.

With 5000 plus patents Loctite leads the category and. The Loctite Design Guide for Bonding Plastics Volume 62 Plastics have become an integral part of everyday life. Thats a big mistake Courtney stresses.

Even products which appear to be composed exclusively of metals are usually coated sealed or adhesively joined. This comprehensive Design Guide contains a description of twelve surface treatments in the Surface Treatments section. The Loctite Design Guide for Bonding Plastics Volume 62.

Elastomeric flexibility improves resistance to vibration fatigue. In bonding plastic feathers and nocks onto arrow shafts 3M Scotch-Weld Industrial Plastic Adhesive dries quickly to a firm bond that resists plasticisers and water. It would be difficult to identify a manufacturing process which does not use plastics in one form or another.

The capability of joining different thermoplastic elastomers in the same assembly is limited to those. The Loctite Design Guide for Bonding Plastics provides bond strength data for 30 substrates including ABS delrin nylon polycarbonate polypropylene polyethylene and PVC. Even products which appear to be composed exclusively of metals are usually coated sealed or adhesively joined using polymeric materials which.

LOCTITE Design Guide for Bonding Plastics. Continuous contact between mating surfaces can effectively bond and seal against many environmental conditions. Two-part adhesive formula includes glue and activator to prime surfaces for a superior bond.

Holes are eliminated maintaining the integrity of the bonded material. Adhesives can accommodate irregular bond lines. Adhesives can successfully displace solvent welding in the plastics industry join dissimilar substrates and provide structural integrity to a wide variety of products and applications.

To keep costs low and bond strengths high plastics and adhesives should be selected at the same time. This can reduce finishing and increase design flexibility. The guide also presents shear strength data on 23 Loctite adhesives including cyanoacrylates epoxies hot melts light cure acrylics polyurethanes silicones and no-mixstatic-mix acrylics.

Loctites continuous commitment to improvement insures constant progress of frustration-free dispensing systems and breakthrough formulations. The design of joints is restricted to geometries which are favorable to the process. 3M Scotch-Weld Epoxy Adhesive.

Loctite Design Guide for Bonding Plastics. Ideally they should have a small uniform contact area to concentrate the ultrasonic energy.

Collar Joining Method Makes Plastic Metal Hybrids Plastics Technology Metal Plastic Method

Plastic And Elastomer Bonding Guide Henkel

Structural Bonding Alternatives For Plastics Plastics Decorating

Loctite Plastics Bonding System

Stick To It A Guide To The Best Glue For Plastic Plastic Glue Best Glue Glue

Simple Guide To Plastic Repair How To Do A Plastic Repair How To Fix A Broken Bumper Pl Cheap Interior Design Interior Design Courses Online Plastic Repair

0 comments

Post a Comment